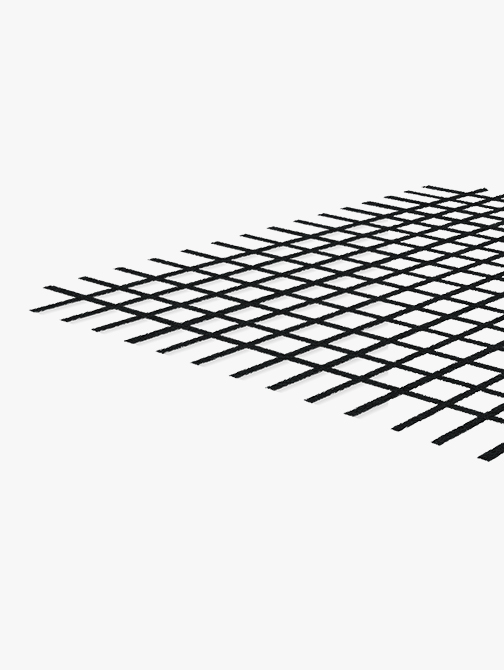

GTF

Reinforcement solutions

ENHANCING THE STRENGTH, SUSTAINABILITY AND LONGEVITY OF ROAD INFRASTRUCTURE

- Become a customer

- Applications & Industries

Areas of Industry Expertise

Airport

Runways

National

Highways

State

Highways

Widening of Roads

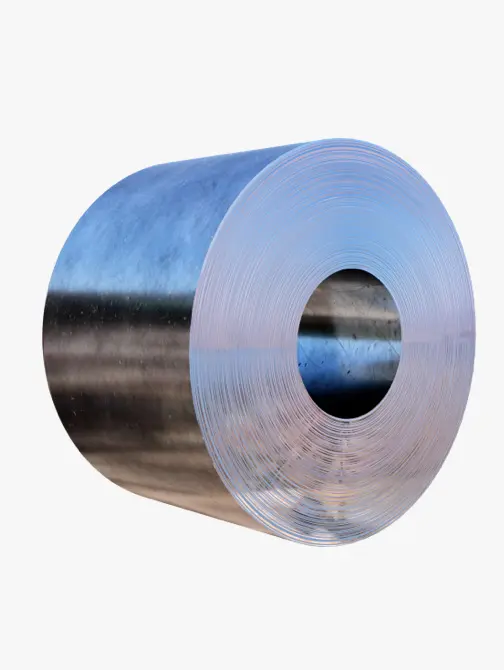

A greener steel provider

As we move forward, we are committed to transparently sharing our sustainability efforts, milestones, and achievements. Through this, we aim to inspire and educate others in the industry, contributing to a more sustainable and responsible steel sector as a whole.

- Solutions

- Eco Innovation

Customer empowerment in a future-focused world

Elevate your applications with Fabrik Process Technology Section. Our expert teams offer cutting-edge solutions, computational modeling, and technical support for a sustainable future across all areas of the business. Join us in driving excellence and innovation.

At Fabrik’s Product Technology Section, our engineers and professionals utilize an extensive range of advanced and sophisticated resources. From cutting-edge testing to modeling and failure analysis, we pave the way for the next generation of steels in virtually every application. In our state-of-the-art laboratories and facilities, the future takes shape.

- Products

our products

- Get In Touch

CONTACT US

BLOGS

GTF WELCOMES ALL FOR INNOVATION

Investor events

Unlocking value through investor events: building relationships, sharing insights, and maximizing opportunities.

Investors

Forging lasting connections with investors: cultivating trust, delivering results, and driving sustainable growth.

Stock information

20 minutes minimum delay | June 9, 2023 4:00 PM EST

- R&D